The Apollo Standard is an Ultrasonic contents gauge that comprises a tank mounted transmitter unit and a plug-in receiver unit. The Apollo Standard is an Ultrasonic contents gauge that comprises a tank mounted transmitter unit and a plug-in receiver unit. The tank transmitter frequently checks the oil level in the tank and transmits this to a plug-in receiver unit which displays the level on the easy-to-read LCD screen. The transmitter unit is compatible with the standard 32mm port fitted to modern plastic oil storage tanks. Optional multi-adaptor ensures compatibility with most steel tanks as well. Premium quality LCD display ensures readability from a wide range of angles under varying light conditions. It also comes equipped with a plug-in receiver unit with integral antenna. APP-STD

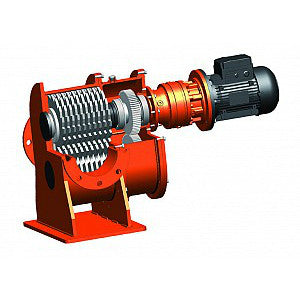

Description Specifications Downloads The CFS series is designed to shred solid materials suspended in the substrate before entering into the digester. It can be supplied with a suction or compression pump or operate under head without a pump. Ideal for shredding long fibres and objects of medium to large dimensions. The system comprises two series of opposing blades with specially designed profiles for shredding solid materials suspended in fluids. A gearbox integrated into the body of the shredder generates different rotation speeds between the two blade support shafts, optimising the process. Applications • Agriculture • Livestock • Food industry • Slaughterhouses • Waste disposal plants

Description Specifications Downloads General Description XMPA06B2131 XMPA12B2131 These are high quality, reliable pressure switches for controlling water pressure booster sets in conjunction with an expansion vessel. Telemecanique pressure switches have adjustable cut out and differential (cut in) pressure to suit your application. These 2 pole N/C (normally closed) pressure switches, are suitable for single phase pumps up to 1.5 kW or as a digital signal to control 3 Phase pumps using a control panel. XMPA06 has a maximum cut out pressure of 6 bar (87 p.s.i.) with a pre-set differential of 1 bar (14.5 p.s.i.) XMPA12 has a maximum cut out pressure of 12 bar (175 p.s.i.) with a pre-set differential of 2 bar (29 p.s.i. XMP Pressure Switch set up info XMP data sheet

Description Specifications Downloads Horizontal tank frames are designed for mounting horizontal tanks for use as liquid transport tanks. These tank mounting frames are manufactured from hot dipped galvanised metal with fork lift points for moving around when empty. Designed for liquids up to 1.5 SG from water to liquid fertiliser and liquid feed, the unique pin mounting system enables these baffled horizontal tanks to be mounted securely without the need for steel mounting straps. Features • Hot dipped galvanised frame with fork lift points • Easy mounting and dismounting when empty • Optional pump plate Code Description 198506 Frame for 171005 & 171010 500 & 700 Litre Horizontal tank 198705 Frame for 171005 & 171010 500 & 700 Litre Horizontal tank with pump plate 198510 Frame for 171012 & 171015 1200 & 1500 Litre Horizontal tank 198512 Frame for 171012 & 171015 1200 & 1500 Litre Horizontal tank with pump plate 198520 Frame for 171025 2000 Litre Horizontal tank 198522

Description Specifications Downloads Code Description 198605-4 Set of 4 mounting pins to suit 400 & 600 FS tanks 198615-4 Set of 4 mounting pins to suit 1200 & 1500 FS tanks 198620-4 Set of 4 mounting pins to suit 2000 FS tanks 198630-4 Set of 4 mounting pins to suit 3000 & 4000 FS tanks 198660-8 Set of 8 mounting pins to suit 6000, 8000, 10000

Various sizes available FEATURES Seamless poly-cotton 10 gauge liner Open back for ventilation and ergonomic design that reduces hand fatigue Conforms to EN388

-e1752673425429.png)