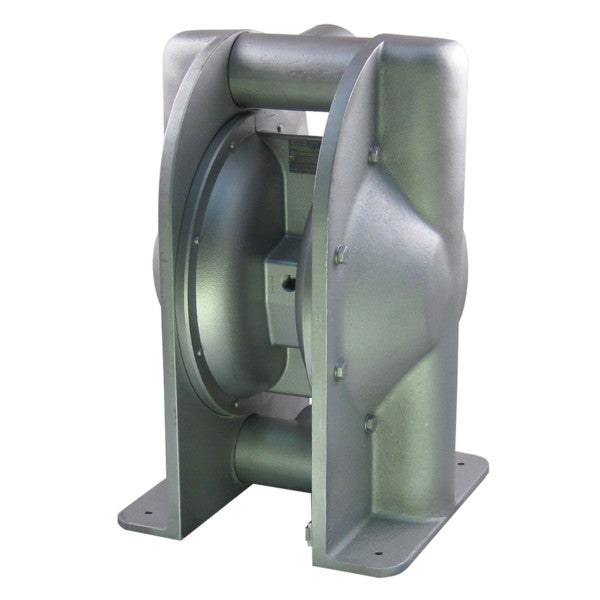

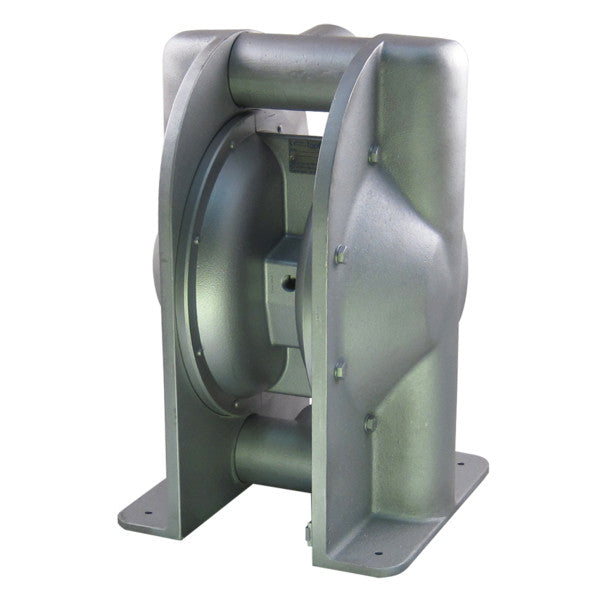

Description Specifications Downloads The compact, smooth and simple design is common for this series. Materials available are aluminium, cast iron, stainless steel and PTFE coated aluminium. You will discover the ingenious simplicity when you maintain the pump. We use approximately 70% fewer parts than our competitors use to build similar sized pumps. Aluminium and cast iron pumps For transfer of pH-neutral fluids, both thin, thick, solid laden or abrasive. The aluminium and cast iron pumps are found in most fields; work shop and paint industries, purifying plants etc., to mention only a few. AISI 316 stainless steel pumps Made in lost wax cast method, ensuring great accuracy and finish. The stainless steel pumps combine great mechanical strength with good chemical features. AISI 316 is resistant to aggressive liquids like nitric acid and sodium hydroxide. The centre unit, which is not in contact with liquid, is made from corrosive resistant polypropylene (PP) as standard (other materials upon request). ATEX certified pumps

Description Specifications Downloads The compact, smooth and simple design is common for this series. Materials available are aluminium, cast iron, stainless steel and PTFE coated aluminium. You will discover the ingenious simplicity when you maintain the pump. We use approximately 70% fewer parts than our competitors use to build similar sized pumps. Aluminium and cast iron pumps For transfer of pH-neutral fluids, both thin, thick, solid laden or abrasive. The aluminium and cast iron pumps are found in most fields; work shop and paint industries, purifying plants etc., to mention only a few. AISI 316 stainless steel pumps Made in lost wax cast method, ensuring great accuracy and finish. The stainless steel pumps combine great mechanical strength with good chemical features. AISI 316 is resistant to aggressive liquids like nitric acid and sodium hydroxide. The centre unit, which is not in contact with liquid, is made from corrosive resistant polypropylene (PP) as standard (other materials upon request). ATEX certified pumps

Description Specifications Downloads The compact, smooth and simple design is common for this series. Materials available are aluminium, cast iron, stainless steel and PTFE coated aluminium. You will discover the ingenious simplicity when you maintain the pump. We use approximately 70% fewer parts than our competitors use to build similar sized pumps. Aluminium and cast iron pumps For transfer of pH-neutral fluids, both thin, thick, solid laden or abrasive. The aluminium and cast iron pumps are found in most fields; work shop and paint industries, purifying plants etc., to mention only a few. AISI 316 stainless steel pumps Made in lost wax cast method, ensuring great accuracy and finish. The stainless steel pumps combine great mechanical strength with good chemical features. AISI 316 is resistant to aggressive liquids like nitric acid and sodium hydroxide. The centre unit, which is not in contact with liquid, is made from corrosive resistant polypropylene (PP) as standard (other materials upon request). ATEX certified pumps

Description Specifications Downloads Aluminium dampeners The aluminium dampeners are perfect to use for pH-neutral fluids. They have great resistance to corrosion and deterioration. They can be found in many applications from workshop, through paint industry to chemistry. AISI 316 stainless steel dampeners Dampeners made of stainless steel offer great mechanical strength combined with good chemical resistance. AISI 316 is resistant to aggressive and abrasive liquids. The dry part of the dampener that does not come into contact with the pumped product is, as a standard, made of corrosive resistant PP. ATEX certified dampeners The dampeners are available in explosion proof – ATEXmarked – execution. They are supplied with earth connection and conductive materials: conductive body, diaphragm in PTFE (conductive backing) or EPDM(conductive). Minimized vibrations and water hammer effects Protection of all kinds of instruments in your pipe system Optimized pump performance and reduced maintenance costs Industry Example of applications Workshop Oil, fat, solvents, water,cooling fluid, lubricants Print & Paint Glue,

Description Specifications Downloads The sanitary series of Tapflo dampeners has been designed in particular for food, beverage, pharmaceutical and cosmetic industries where cleanliness and sterile environment is necessary. Made to be clean The dampener is designed and prepared for cleaning and sterilization in place – C.I.P. and S.I.P. These are automatic cleaning and disinfection procedures implemented in these industries so it is essential that our product are prepared to comply with these procedures. ATEX certified dampeners The dampeners are available in explosion proof – ATEXmarked – execution. They are supplied with earth connection and conductive materials: conductive body, diaphragm in PTFE (conductive backing) or EPDM(conductive). Minimized vibrations and water hammer effects Protection of all kinds of instruments in your pipe system Optimized pump performance and reduced maintenance costs Industry Example of applications Dairy products Milk, cream, yoghurt, cream cheese,melted cheese Grossery Ketchup, mayonnaise, tomato, products,mustard Beverages Flavours, colouring, fruit juice Bakery Dough, ingredients Brewery Beer, flavours, colouring, wort Hygiene Soap,

Description Specifications Downloads Polyethylene (PE) dampeners Hi-Density Polyethylene (PP HD) has better physical and chemical parameters than standard polypropylene (PP). It is several times more resistant to wear what makes this material ideal for abrasive and aggressive liquids. It can also withstand liquid temperature up to 70°C. PTFE dampeners PTFE is excellent for use in applications requiring high temperatures. It may also be used for very aggressive fluids such as chlorinated hydrocarbons and highly aggressive acids. Maximum liquid temperature is 100°C ATEX certified dampeners The dampeners are available in explosion proof – ATEXmarked – execution. They are supplied with earth connection and conductive materials: conductive body, diaphragm in PTFE (conductive backing) or EPDM(conductive). Minimized vibrations and water hammer effects Protection of all kinds of instruments in your pipe system Optimized pump performance and reduced maintenance costs Industry Example of application Chemistry Acids, alkalis, solvents, latex, emulsions Food CIP fluid, flavouring, pigments Pulp & Paper Glue, slurries, adhesives, dispersions, resins, sodium,silicate,

-e1752673425429.png)